AMEFO, your protection systems expert

Over the years, AMEFO has developed its expertise and proved its know-how to become a leading player in the Defense industry.

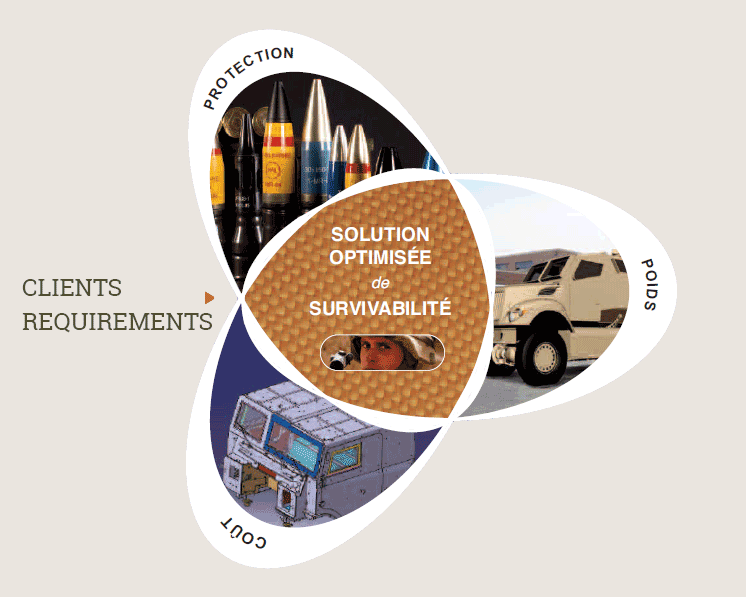

AMEFO manages complex projects for its customers relying on:

- Threats knowledge and understanding of their effects

- Protection materials mastering and implementation

- Experience in qualification procedures

- Conception oriented toward crew’s protection (ergonomics and survivability included), while preserving vehicle performance

- Dedicated and responsive teams

Continuous research & development monitoring:

- Responses to new threats

- Conception, implementation and improvement of new protection materials

- Use of modeling and simulation tools

- Field testing

Download our commercial brochure

|

AMEFO Armor Solutions |

Anti-spall liners

AMEFO provides anti-spall liners to improve the initial protection level of land vehicles against ballistic threats and flying debris inside the cabin caused by the impact with the vehicle’s metallic walls. In addition to the armored cabin, AMEFO designs, produces and installs anti-spall liners in every critical part of the vehicle to improve on-board survivability.

- Use of certified materials:

- Glass fiber

- Aramid: Kevlar®, Twaron®

- High performance polyethylene: Dyneema® UD, Endumax®, Spectra Shield®, Tensylon™

- Neutralization and reduction of flying debris

- Adaptable cut and dimension, tailored to fit in any type of vehicle

- Available in assembly kit or integrated by AMEFO on the in-house production line

Its latest advances enable AMEFO to provide:

- Thermoplastic resin based liners, an AMEFO/PLASAN exclusivity, combining high temperature resistance and absence of volatile organic compounds (VOC) inside the cabin

- Flexible/bendable liners fitting vehicles’ slight curves or to facilitate the integration in parts difficult to access

- 3D molded liners that can be adapted to complex vehicle shapes

Add-on armor kits and window glasses

- Use of various ballistic materials: armored steels, composite materials, ceramics

- Light solutions that do not impact the vehicle’s performance

- SBC Steel Based Composite, AMEFO’s innovation combining the resistance and ease of integration of armored steel and composite light weight

- Bullet proof Windows and window frames

- Available in assembly kits or integrated by AMEFO on the in-house production line

- Modular solutions allowing easy mounting/dismounting by the crew, without special equipment