AMEFO designs and produces armor solutions for planes and helicopters

In cooperation with your teams, we design the most optimal protection for any type of aircraft, focusing on:

- Crew protection

- Mobility

- Design

- Isolation

Our solutions respond to the following requirements:

- Protection adapted to the interior configuration of any type of aircraft

- Considering flying constraints (Favorable load distribution inside the aircraft etc.)

- Protection materials selection following the type of threat (including 12.7 caliber)

- Multi impact resistance

- Environmental constraints resistance (humidity, thermal shocks, vibrations, fire resistance…)

- Mass/protection ratio optimization

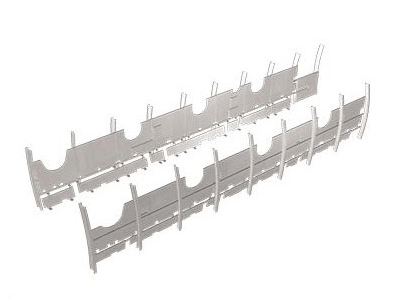

- Modular solutions allowing easy mounting/dismounting by the crew

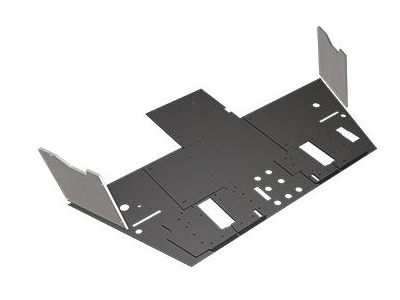

Cockpit protection, modular floor and inside lateral panels

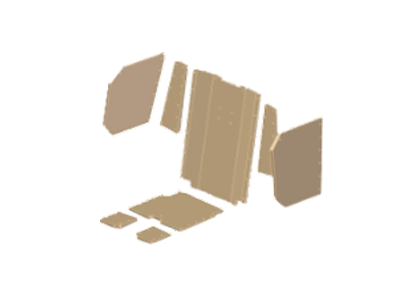

AMEFO produces modular floors and anti-spall liners against ballistic threats and flying debris for all critical parts of aircrafts to improve the survivability of the crew.

- Lightweight solution that does not affect the aircraft’s performance in Ceramic & composite materials

- Use of certified materials:

- Glass fiber

- Aramid: Kevlar®, Twaron®

- High performance polyethylene: Dyneema® UD, Endumax®, Spectra Shield®, Tensylon™

- Assembly Kits and spare part delivery

- custom made to match the dimensions that best meet your requirements

Its latest advances enable AMEFO to provide:

- Ceramic panels of different purity to find the most suitable weight/protection/cost ratio

- Thermoplastic resin based liners, an AMEFO/PLASAN exclusivity, combining high temperature resistance and absence of volatile organic compounds (VOC) inside the cabin

- Flexible/bendable liners to fit vehicles’ slight curves or to facilitate the integration in parts difficult to access

- 3D molded liners that can be adapted to complex aircraft shapes