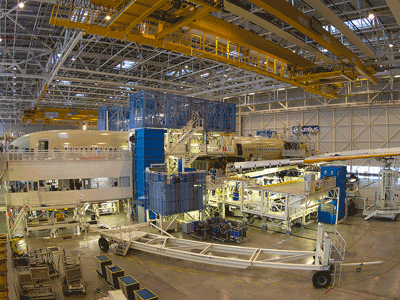

Tooling, assembly and maintenance for the aerospace industry

AMEFO designs and produces equipment and tooling enabling the transport of aircraft parts, implements the final assembly line and provides vehicle maintenance.

To comply to the aircraft industry needs and requirements regarding development time and tooling weight, AMEFO relies on its:

- Know-how in mechanical welding to provide the most optimal solutions

- Quality and precision parts production

- Capacity to deliver a complete set

- Competences to work in simultaneous engineering

AMEFO’s experience in project management and simultaneous engineering ensure to its partners:

- Management of project development

Project performance achievement at the best cost

Compliance to quality requirements

Integration of different working constraints into the production process

Project planning

On-time delivery

Following the needs and the requirements of your project, we provide:

Capacity to establish a manufacturing file from dimensioned drawings

Production processes control (cutting, sawing, folding, machining, surface treatment…)

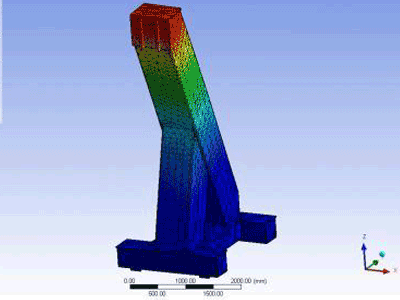

Mastering welding processes and associated tools manufacturing. Capacity to follow specific tolerances, from little to large dimensions.

Welding standard operation procedure certifications

Non-destructive quality control techniques (dye penetrant, radiographic, ultrasonic and magnetic testing), COFREND 2 certification of our control staff

Prototype validation through an independent and approved external body before production

High reactivity to put in place a production line with reliable processes

Traceability documentation system following requirements