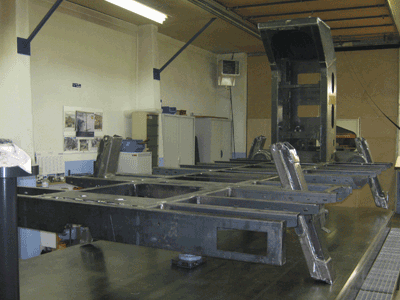

Complex lifting device subassemblies conception and production

AMEFO has a long-time experience in the production of mechanically welded subassemblies for lifting devices. This knowhow is certified through the approval of a qualified independent body and by relevant studies based on feedbacks from the field.

AMEFO also responds to specific demands for single parts in small quantity, spare parts, repair and maintenance.

AMEFO’s experience in project management and simultaneous engineering ensure to its partners:

- Management of project development

Project performance achievement at the best cost

Compliance to quality requirements

Integration of different working constraints into the production process

Project planning

On-time delivery

Following the needs and the requirements of your project, we provide:

Capacity to establish a manufacturing file from dimensioned drawings

Production processes control (cutting, sawing, folding, machining, surface treatment…)

Mastering welding processes and associated tools manufacturing. Capacity to follow specific tolerances, from little to large dimensions.

Welding standard operation procedure certifications

Non-destructive quality control techniques (dye penetrant, radiographic, ultrasonic and magnetic testing), COFREND 2 certification of our control staff

Prototype validation through an independent and approved external body before production

High reactivity to put in place a production line with reliable processes

Traceability documentation system following requirements